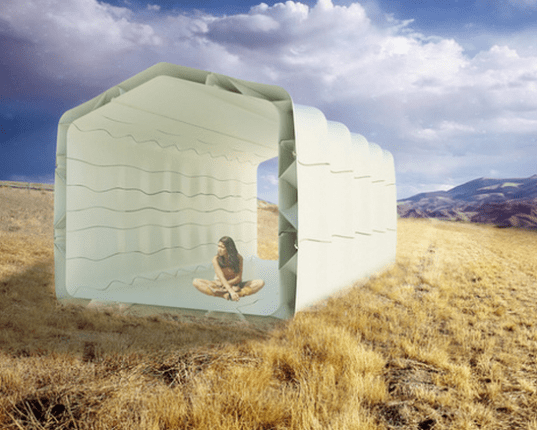

Schoch and Lee utilized a Euclid Robot 3d printer with ABS as their material of choice, and because the components are tough, exact and durable, the structure is easy to assemble. A larger structure would only require minimal equipment to put together.

A tension element on the outside of the structure has a hook and matching receptacle, and combined with a compression element on the inside is sufficient to keep water out. Accommodations can be made for mechanical systems as well as piping in water, arranged for by using the 3D printing process.

Because of the affordability and quick production and assembly, MHProNews understands this product could be extremely useful to house people following a catastrophic event. ##

(Image credit: 3dprint/Eugene Lee)